Removing Operational Waste in Safety Processes:

A Guide to Operational Safety Excellence

Safety processes, such as Permit-to-Work (PTW) and Lockout/Tagout (LOTO), are not immune to operational waste.

In high-risk industries, such as manufacturing, construction, and energy, safety processes are crucial in protecting workers and preventing accidents. However, no plant management wants to achieve 100% safety and go bankrupt. Operational waste refers to any activity, practice, or resource that does not add value to the overall safety process, leading to inefficiencies, delays, and increased risk. And thus, increased costs.

In this article, we will continue to explore the various types of waste in safety processes and discuss strategies to remove them, ultimately achieving Operational Safety Excellence.

Waste Types in Safety Processes Overview

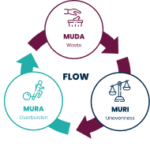

The concept of operational waste originated from Lean Manufacturing, a management philosophy, and methodology developed by Toyota in the mid-20th century. Lean Manufacturing aims to eliminate waste and increase efficiency in manufacturing processes. One of the central principles of Lean is the identification and reduction of various types of waste, often referred to as “Muda” in Japanese.

Over time, the concept of waste in Lean Manufacturing expanded beyond the realm of manufacturing and was applied to other industries and processes, including safety processes. Operational waste in safety processes refers to activities, practices, or resources that do not contribute value to the overall safety objectives and may lead to inefficiencies, delays, increased risk, and compromised safety.

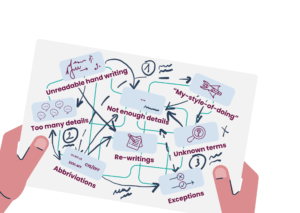

- Waiting: Delays caused by waiting for approvals, authorizations, or equipment availability.

- Defects: Erroros, re-dos, misalignments that lead to production losses and avoidable risks.

- Overproduction Waste: Excessive production of safety documentation or redundant safety checks.

- Unnecessary movement: searching for tools, equipment, or information, movement of documents, personnel.

- Overprocessing: getting too many non-value-adding authorizations and duplicated paperwork.

- Inventory Waste: Excess inventory of safety supplies, such as personal protective equipment (PPE).

- Unused employees’ creativity: not using the expertise and enthusiasm of shopfloor people to improve safety processes.

These waste types contribute to inefficiencies and delays in safety processes, but by addressing them effectively, organizations can improve overall safety performance. We have reviewed them in detail in the following video series.

The Mindset Required to Remove Waste

Removing operational waste in safety processes requires more than just implementing strategies and methodologies. It requires a specific mindset within the organization, emphasizing a commitment to continuous improvement and a proactive approach to waste reduction. In this chapter, we will explore the key elements of the mindset necessary to effectively remove waste in safety processes.

Being Ready to Change

Embracing change is crucial when aiming to eliminate operational waste in safety processes. It requires a culture that is open to new ideas, willing to challenge the status quo, and receptive to feedback and suggestions from employees at all levels. Leadership plays a vital role in fostering this mindset, promoting a culture of innovation and improvement, and encouraging employees to participate in waste reduction initiatives actively.

Long-term vs. Short-term Vision

Removing operational waste is not a one-time effort; it requires a long-term vision. Organizations must prioritize sustainability and view waste reduction as an ongoing process rather than a short-term fix. While immediate gains may be achieved through specific initiatives, it is essential to maintain a broader perspective, continually seeking opportunities for waste elimination and striving for Operational Safety Excellence.

Lean is Not Just About Cost-Cutting

A common misconception is that lean practices and waste reduction initiatives are primarily about cost-cutting. While cost reduction can be a positive outcome, the primary focus of lean methodologies is on value creation, process improvement, and enhancing safety outcomes. The mindset required for waste removal should emphasize the pursuit of safety excellence and the well-being of employees, aligning with the organization’s mission and values.

Data-Driven Decisions

Data is a powerful tool for waste removal in safety processes. The mindset should emphasize the importance of data-driven decision-making, leveraging available data to identify waste, measure progress, and inform improvement efforts. Collecting and analyzing relevant safety metrics, incident data, and performance indicators will provide valuable insights and guide decision-making toward the most impactful waste reduction strategies.

By cultivating this mindset throughout the organization, safety processes can be continuously improved, waste can be reduced, and the path to Operational Safety Excellence can be achieved.

Removing Operational Waste: Methods and Tips

Various methods and principles can be applied to identify and eliminate waste effectively. The organization should choose methods that match its goals and available resources. Here are some proven methods and practical tips for removing operational waste in safety processes.

One of the fundamental methods for waste removal is the practice of Gemba, which means “the place of action” in Japanese. Gemba emphasizes the importance of going to the actual location where work is being done to observe and understand the processes firsthand. By engaging with frontline workers, managers can gain valuable insights into waste sources, identify non-value-added activities, and collaboratively find solutions to eliminate waste.

Practical Tip: Regularly schedule Gemba walks to actively observe safety processes, engage with workers, and encourage open communication to uncover waste and improvement opportunities.

Kaizen: Continuous Improvement

Kaizen, meaning “change for the better” in Japanese, is a methodology that focuses on continuous improvement. It involves empowering employees at all levels to contribute to waste reduction by identifying and implementing small, incremental changes. Kaizen promotes a culture of continuous learning, encourages problem-solving, and fosters employee engagement in the pursuit of waste elimination.

Practical Tip: Establish a formalized process for collecting and implementing employee suggestions for waste reduction. Regularly review and recognize successful Kaizen initiatives to sustain a culture of continuous improvement.

Value Stream Mapping is a powerful tool for visualizing the flow of information, materials, and activities within a safety process. It helps identify waste, bottlenecks, and areas of improvement by mapping the current state and developing a future state VSM. By visualizing the entire process, organizations can prioritize waste reduction efforts and develop a roadmap for process optimization.

Practical Tip: Engage cross-functional teams to create collaborative value stream maps, ensuring a holistic perspective and encouraging diverse insights for waste identification and elimination.

5S Methodology: Sort, Set in Order, Shine, Standardize, and Sustain

The 5S methodology focuses on organizing and standardizing work areas to eliminate waste and improve efficiency. The five principles provide a systematic approach to workplace organization, leading to improved safety, reduced motion waste, and enhanced productivity.

Practical Tip: Implement regular audits and visual management techniques to sustain the 5S practices, ensuring a clean, organized, and efficient work environment.

Remember to foster a culture of continuous learning and embrace data-driven decision-making to drive effective waste reduction efforts. By actively addressing operational waste, organizations can enhance safety performance, mitigate risks, and strive for Operational Safety Excellence.

The Role of Digitalization in Removing Waste in Safety Processes

The integration of digital technologies can significantly contribute to waste reduction and enhance safety performance. Here are some key ways digitalization can support the removal of operational waste in safety processes:

- Automation and Digitization: Manual processes, paperwork, and documentation can be time-consuming and prone to errors. By automating and digitizing safety processes, organizations can eliminate waste associated with manual data entry, document handling, and approval workflows. Digital platforms and software solutions can streamline PTW and LOTO processes, enabling real-time collaboration, electronic approvals, and improved traceability.

- Data Analytics and Insights: Digitalization allows organizations to collect and analyze large volumes of safety data. By leveraging advanced analytics and artificial intelligence, patterns and trends can be identified, enabling proactive risk mitigation and waste reduction. Predictive analytics can help anticipate safety hazards, optimize resource allocation, and identify opportunities for process improvement.

- Mobile Applications and Wearable Technology: Mobile applications and wearable devices offer real-time access to critical safety information, checklists, and procedures. This reduces the waste associated with manual information retrieval, improves communication, and ensures that workers have the right information at their fingertips. Wearable technology can also provide real-time monitoring of vital signs and environmental conditions, enhancing worker safety.

- Integration and Interconnectivity: Digital systems can integrate various safety processes, allowing for seamless information flow and reducing waste associated with redundant data entry and communication gaps. Integration with other operational systems, such as maintenance and scheduling, ensures that safety considerations are incorporated into overall operational planning, further enhancing efficiency and waste reduction.

- Visualization and Reporting: Digital platforms enable the creation of interactive dashboards and visualizations, providing a comprehensive overview of safety performance indicators. Real-time reporting and monitoring facilitate timely identification of waste and areas for improvement. Visual representations of data can also enhance communication and understanding among stakeholders, promoting a shared focus on waste reduction and safety excellence.

Moreover, digitalization enhances personnel, thus helping to eliminate the most precious waste – unused employees’ creativity. Read more about How Digitalization Makes People Think.

Conclusion

Removing operational waste in safety processes, such as permit to work and lockout/tagout, is essential for achieving Operational Safety Excellence. By understanding and addressing different types of waste, implementing lean principles, and leveraging digitalization, organizations can streamline safety processes, reduce inefficiencies, and enhance overall safety performance. The journey towards Operational Safety Excellence requires commitment, engagement, continuous improvement, and using digital tools to drive waste reduction and create a safety-first culture. By embracing these principles and methods, organizations can ensure the well-being of their workers, mitigate risks, and achieve operational excellence in safety.

If you want to learn more about how Unite-X can support you in your continuous improvement journey, contact us today.