Roots of the most of the Permit-to-Work process challenges

Why do we still often see issues with building and implementing an effective digital Permit to Work safety process?

At Unite-X, we always start with Kaizen, a session where everyone involved in the Permit to Work safety process is able to co-design the flow in the most efficient way. We do so because we believe that an improvement and simplification of the flow should always precede digitalization.

In this article, we sneak peek into the way of thinking about the foundation of problems and how to approach them to start the journey of continuous improment.

Cascading consequences effects

Imagine Permit-to-work as a complex ecosystem with many unequal steps, elements, attributes, multiple stakeholders, and processes influencing it. These types of systems with many interconnections usually experience the effects of cascading consequences or chain reactions, like the “butterfly effect,” “domino effect,” “snowball effect,” and “iceberg effect.”

These effects are different phenomena where a small initial action can lead to significant and sometimes unexpected outcomes. At a closer look, Permit-to-Work on paper all these effects have a lot of negative impacts. Let’s see in detail below how:

Butterfly Effect is a concept from chaos theory that suggests that a small change in one state of a deterministic nonlinear system can result in large differences in a later state. For instance, a typo in the permit handout could set off a chain of reactions leading to a production incident.

It highlights how sensitive paper systems can be to initial conditions, stressing the importance of enhancing small actions in complex systems.

The Domino Effect refers to a situation in which one event sets off a chain of similar events, like a falling domino causing an entire line to topple over. Permit-to-work on paper is a perfect example of when you need to make an edit in one handout and then make the same edit in the mountain of other papers, too.

It underscores the interconnectedness of events and the potential for a single action to trigger a series of consequences.

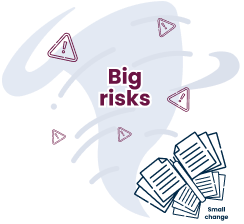

The Snowball Effect describes a process that starts small and builds upon itself, becoming larger and more powerful. Imagine rolling a small snowball down a hill; it gathers more snow and grows bigger and faster as it descends. Just like a one-step adjustment in permit-to-work that started small can suddenly evolve into a big and costly project (making the initiator think twice next time before proposing an improvement).

It shows how actions can gain momentum, escalate, and go out of control.

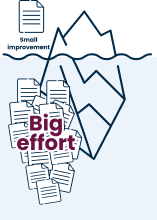

The Iceberg Effect, as a metaphor, highlights that a small visible part of a problem or situation (the tip of the iceberg) is just a small indication of a much larger and more complex underlying issue.

It emphasizes the importance of looking beyond the surface to understand the full scope of a situation, making it crucial in fields like the engineering of the permitting process.

In our experience running over a few hundred sessions, we see how these effects generate other problems with permitting processes:

- Operational Waste: The process is not efficient and full of operational waste

- Lack of Ownership: People are not engaged and avoid taking ownership of the process

- Missing Hazard Controls: The process is not 100% safe and is missing important hazards and control measures

Now, let’s look at these more in detail.

Lack of Ownership

This could be a classical “chicken or egg” dilemma: Is the process inefficient because people do not own it, and thus errors and imperfections create unnecessary risks? Or vice versa — people avoid owning it because it will bring too much of a hassle to perform?

We put people first at Unite-X and truly believe in the power of joint creativity and engagement. Therefore, we focus on improving the Permit to Work process in a way that supports, engages, and guides people toward operational excellence.

The lack of ownership over the Permit to Work safety process can lead to disastrous results, so it’s important to understand why people aren’t taking part in it. Moreover, there is a constant popular thought that safety is a standalone department and the headache of a responsible EHS person only.

Behaviors triggered by an inefficient process

When people are overburdened or overwhelmed, they are not in the best emotional state to make decisions. They might neglect issues, forget things, and skip important steps.

If you are constantly rushing, you lose track of what is happening around you and only focus on the most urgent things. In this frame of mind, you forget about improvements and future developments.

These behaviors are clearly triggered by inefficient processes and a lack of tools, which can lead to injuries and incidents. Read more on the topic here.

Why do people avoid owning a Permit-to-Work process?

In addition to the feeling of overwhelm and overburdened by inefficient processes, there are other reasons why people avoid owning the Permit-to-work process. Here are some of the main reasons:

- If the Permit-to-work safety process is too complicated and unclear, people avoid taking a role in it, trying to get rid of unnecessary hassle

- Being under pressure for a long time eventually leads to frustration, boredom, or a “Why bother if nothing changes?” attitude.

- Lack of trust, when people are simply afraid to say things aloud because of internal leadership culture, might lead to unrealized improvement initiatives. (There is a great book about it, “The Five Dysfunctions of a Team” by Patrick Lencioni)

- In the manufacturing industry, people tend to work long periods at one position, which creates complacency and an “it has always been like that” state of mind.

All of these are examples of behaviors that create potential room for risky actions. The good news is that a well-designed Permit to Work safety process can support a team in overcoming or avoiding these behaviors

Operational Waste

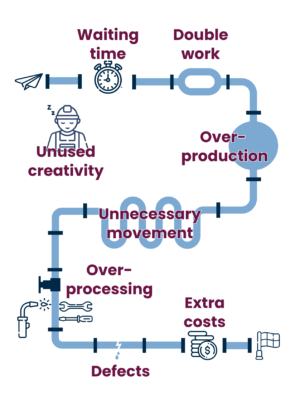

The first challenge is an excess of operational waste—the PtW process is not efficient. Waste is a type of activity that doesn’t bring value to the client (i.e., to the team that operates the PtW process in our case) and does not contribute positively to safety.

At Unite-X, we believe that a leaner process is a safer process. Operational waste like waiting time or unnecessary movement triggers risky behaviors and forces people to cut corners on safety and costs organizations avoidable costs.

How to identify waste

So, how do you know if your Permit to Work process is full of waste? Most people avoid taking ownership of inefficient processes, so observing your team’s perceptions could be the first step to understanding the process better.

Here are some signs of a badly designed Permit to Work process:

- If your team is often rushing

- If you often see a contractor sitting and waiting hours for permits before they can start

- If tasks are often stuck, and projects do not progress

- If you see a lot of re-dos, false steps, unclarity, and errors

- If it is hard to plan or opposite planning doesn’t work

These common waste signals are important to pay attention to. Try not to blame others, but simply pay attention to the hurdles that are in the process itself.

Reasons for waste

There are many reasons why operational waste arises. It could be a result of poorly designed procedures or human neglect.

During our 20 years of observing Permit to Work safety processes around the globe, we defined three root problems:

- Lack of full process overview: This is when team members have “tunnel vision,” being too focused on their part of the process and missing the full picture.

- Lack of standardization: This refers to teams who do not re-use what was already improved and created and start from scratch every time

- Lack of necessary tools: This is not necessarily software but methods and techniques that help to create situational awareness and to monitor the process, like Gemba, measurements and KPIs, kaizens sessions, etc.

Tackling these three problems decrease operational waste and help to build a smooth Permit to Work process.

You can watch a series of videos about each waste type here.

Missing Hazard Controls

The last root issue with the Permit to Work safety process is that we still often see that it does not ensure a 100% safe work environment, even if it is fully compliant and established.

Even if you have a great process in place and a robust software program, important hazards, and control measures could be left out. Why?

The job is done by people. People configure the software according to their expertise and knowledge. Sometimes, their expertise is simply not enough to manage a particular case. This is very relevant for smaller sites, where they have limited access to experts.

By reusing a permit template with missing hazards, you create a “snowball effect” and duplicate the wrong permit to work handouts over and over.

The same comes to control measures. Your peer might use a better way to protect people, but you might be unaware of that, even if you are using the same software.

Thus, the process should be built in a way to contain all available safety expertise, best practices, and lessons learned in order to help people to avoid human errors and to guide them through the safeties possible path.

How to improve your Permit-to-Work?

So, what’s the solution to building a solid foundation for an efficient and safe Permit-to-work process?

At Unite-X, we believe that a permit-to-work safety process should be well-designed, clear, and transparent. This way, everyone following it can make the best choice possible.

In other words, if you want to go from A to B, follow the process, and you will go the most optimal and safe way.

We at Unite-X have created the “3E Model” to address the above-mentioned challenges:

- Engage: involve people in designing the process to ensure their buy-in and ownership, support and educate them constantly

- Enhance: Be aware of the existing operational waste, tackle it, measure it, and focus on eliminating it from your process.

- Embed: choose the Permit to Work software that already contains the most effective best practices and the safest path of work proven by industry leaders.

All three principles we apply while implementing Unite-Permit to Work with our structured implementation framework.

Conclusion

The “chicken and egg” dilemma with the Permit to Work safety process issues can be solved by realizing everything is interconnected and impacts each other. People avoid owning inefficient processes, and inefficiencies in the process appear when no one owns them.

With Unite-Permit to Work, we do not tackle these elements separately but work with all of them to create synergy.

Award-winning safety software matching your needs

Unite-Permit to Work is a robust software system that helps to meet the challenges of people who take care of safety in hazardous manufacturing.

In this brochure, prepared by Unite-X experts, you will:

- Read about common challenges people at different organizational levels and roles face in the Permit-to-Work process

- Explore offered solutions both from Safety and Effectiveness perspectives

- Sneak peek at Unite-Permit to Work functionality

- Evaluate achieved measurable results and benefits

Ready to learn more about the Unite-Permit to Work solution by Unite-X? ->

Download the Unite-Permit to Work brochure