We at Unite-X believe that implementing safety policies in the plant is not supposed to slow things down. Like any other process, safety activities flow should be smooth and approach maximum productivity.

But also we found out that…

Lean process is actually safer!

Adequate process flow prevents risky behavior, eliminates potential risk triggers, and elevates safety levels.

For over 20 years, Unite-X gathered and developed industry knowledge and best practices on how to elevate the safety level, save costs and increase employee involvement.

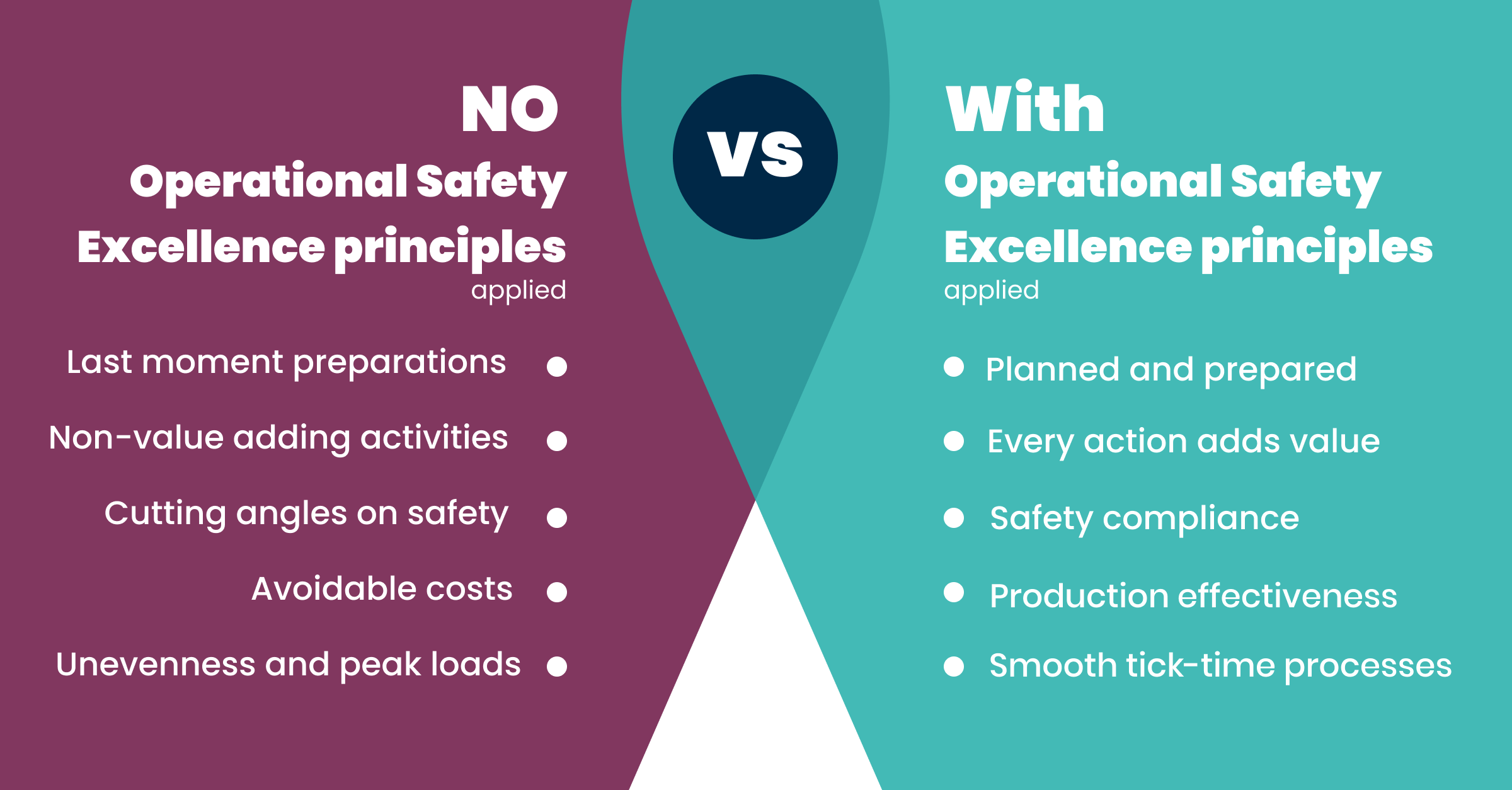

The Operational Safety Excellence domain, developed by Unite-X experts, focuses on applying principles of Lean manufacturing to safety processes.

Do you want to discuss the Operational Safety Excellence domain?

Digitalization for Excellence

There is an overlap between digitalization, lean approaches, and zero incidents that creates necessary synergy for the continuous improvement journey.

Digitalization positively impacts incident rates, saves time and resources, and frees hands and minds from unnecessary work. Explore the way Unite-X approaches safety processes digitalization

Get inspired by leaders

Our clients consider Operational Safety Excellence as their North Star on the way towards continuous improvement. Applying its principles unlocks new possibilities to elevate their safety and productivity levels.

Learn more about how industry leaders like DSM, Sabic, and Nouryon utilized Unite-X to meet their challenges.

Featured webinar

How safety experts could benefit from Lean methodologies?

On-demand webinar: Lean for Safety professionals

As a safety expert, you want to ensure that your processes are 100% compliant to reach zero.

But what if performing safety measures slows down manufacturing flow?

Watch the on-demand webinar to explore the view on safety from the Lean methodology point of view.