LoToTo: How to Organize a Highly Complex Process

Keeping track of the LOTOTO process and ensuring that each action is given the proper attention it deserves is a real challenge. In this article, we overview how to deal with the complexity of the LOTOTO (Log Out Tag Out Try Out) to achieve Operational Safety Excellence.

People vary in their ability to manage many small details. Some individuals have a natural talent for it and can stay organized and focused even in the midst of chaos, while others may struggle to keep track. But when it comes to risky processes, human errors are unacceptable.

LOTOTO procedure is as a system of checklists and actions that demands high attention to detail.

According to the Occupational Safety and Health Administration (OSHA), approximately 120 fatalities and 50,000 injuries occur yearly due to inadequate LOTOTO procedures.

That makes LOTOTO a process with extremely serious consequences and endless opportunities for human errors.

Complexity of LOTOTO

The LOTOTO is a process that consists of many small details that need to be managed properly to ensure the safety of workers. Isolating and de-energizing equipment, placing locks and tags on energy sources, and verifying that the equipment is safe to work on before maintenance or repair work can begin to require attention to detail and careful management.

Additionally, LOTOTO procedures often involve multiple stakeholders, such as operators, maintenance personnel, and supervisors, who must coordinate and communicate effectively to ensure the process is executed properly.

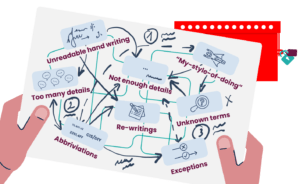

Surprisingly many plants still organize their LOTOTO process on paper, leveraging complex systems of Excel sheets, documents, semi-automated connections, printings, and handwriting.

Managing a process that consists of papers and handwritten notes often also involves oral agreements, inconsistencies, misunderstandings, and unknown factors on top.

To put it another way, keeping many small details in order is like trying to organize a room full of cats. Just when you think you’ve got everything under control, one cat jumps on the bookshelf, another knocks over a vase, and the rest start running in circles. It easily becomes overwhelming and can quickly turn into chaos, a never-ending cycle of energy-draining actions needed to keep everything in order.

Each person involved in the process may have a different understanding of the requirements, leading to errors and inconsistencies. Handwritten notes can be difficult to read or misplaced, leading to confusion and delays. Unknown factors can arise unexpectedly, making it challenging to plan.

Under these circumstances, LOTOTO is a process that is very hard to scale up, speed up or hand over.

Manage the chaos

So, how do you optimize LOTOTO to avoid the issues described above? We at Unite-X promote the approach that consists of the main areas:

- Standardization: Streamlining processes to eliminate operational waste and minimize risks.

- Verification: Proving that the equipment or process is safe by focusing on the “Try-out” part of LoToToTo.

Standardization

Standardization is the best thing a plant or factory can do to support its operational safety goals. Through standard processes and procedures, you can minimize waste and maximize efficiency. It means you don’t have to start everything from scratch or compete with each other’s local templates like some notes written down somewhere.

With LoToToTo, standardization makes a complex process simple and manageable. It brings the value of LoToToTo into a process that everyone can follow.

The key benefits of standardization for LoToToTo are:

- Making a complex process simple.

- Ensuring everyone is on the same page.

- Eliminating operational waste.

With a standard approach to managing things, people start a process with a question: “What is different this time?” instead of “What do I need to do?”, Read more about standardization in our previous article.

Standardization also opens new opportunities for global organizations that aim to spread out their safety culture across sites all over the globe.

Download Unite-LoToTo product brochure

Please fill out the form below to download the brochure

Verification

Sometimes in public discussions and professional slang, we hear that the process of LOTOTO is called LOTO instead of LOTOTO, where the last “TO” is left out. This is cannot be intentional, indeed the part with verifying is given less priority. However, verification is a crucial ingredient of the optimal LOTOTO, last, but not least.

Without trying out your equipment and proving it is safe, you are not assuring your team members that they will not be hurt.

Even if you have the best staff and highly qualified employees, there is room for human error. And, if you think about it from the workers’ perspective, they just want to know: is this safe?

Try-out is an essential part of LoToToTo because it verifies and proves that the equipment is safe.

Example: Many plants work with steam, which can cause significant injury. In the LoToToTo process, you are turning off one steam pipe. But, because of human error or lack of standardization, the wrong one was closed. So, as a next step to ensure safety, you need to “try-out” the pipe and check to ensure it was done correctly. This will prove to the workers that there is no energy in the pipe that will hurt them.

Don’t just focus on lock-out, tag-out with your safety processes—Try-Out is such an important part of it because it proves safety. Doing this will not only ensure that there are no incidents, injuries, or deaths, but it inspires trust with your team members.

Implementing Effective LoToTo Processes

It’s important to note that standardization and verification in the LoToTo process are not vague ideas or solutions that don’t work in the “real world.” They are real areas of focus for plant managers.

Too often, people think the solution for operational safety excellence is to just hire better staff or to have higher standards. But there are a few issues with this idea:

- There is a staffing shortage, so it’s hard to hire team members already.

- It’s too simplistic. Even the best employees are prone to human error.

- It doesn’t account for the challenges with LoToToTo (complexity, lack of standardization, etc.).

A better approach is to ask, “What went wrong today, and how can we fix it?”

This keeps people in the present instead of worrying about the past and the future. They can work with real problems and situations, find creative ways to resolve them and improve things for the future.

To implement a successful LoToToTo process, it’s also important to keep track of metrics such as how many standardized templates are being created (there should be one for each piece of active equipment) and how much waste or rejects there are.

Conclusion

High attention to detail, focus, and organization is usually mentally exhausting and creates stress and anxiety, especially when dealing with high-stakes projects or situations where mistakes can have serious consequences. At a time when there is a staffing shortage, it is crucial for leaders to think of ways to support teams best, make them feel valued, and not be overwhelmed with managing too many details.

Standardization and verification are critical to a successful LoToToTo process to strive for operational safety excellence.

Implementing a successful LoToToTo process means that you need to have the right tools. Unite-X is top-notch safety software to achieve operational safety excellence. It can help you streamline and standardize your processes, optimize operations and keep everyone safe.

If you want to learn more about how Unite-X can work with your company, contact us today.