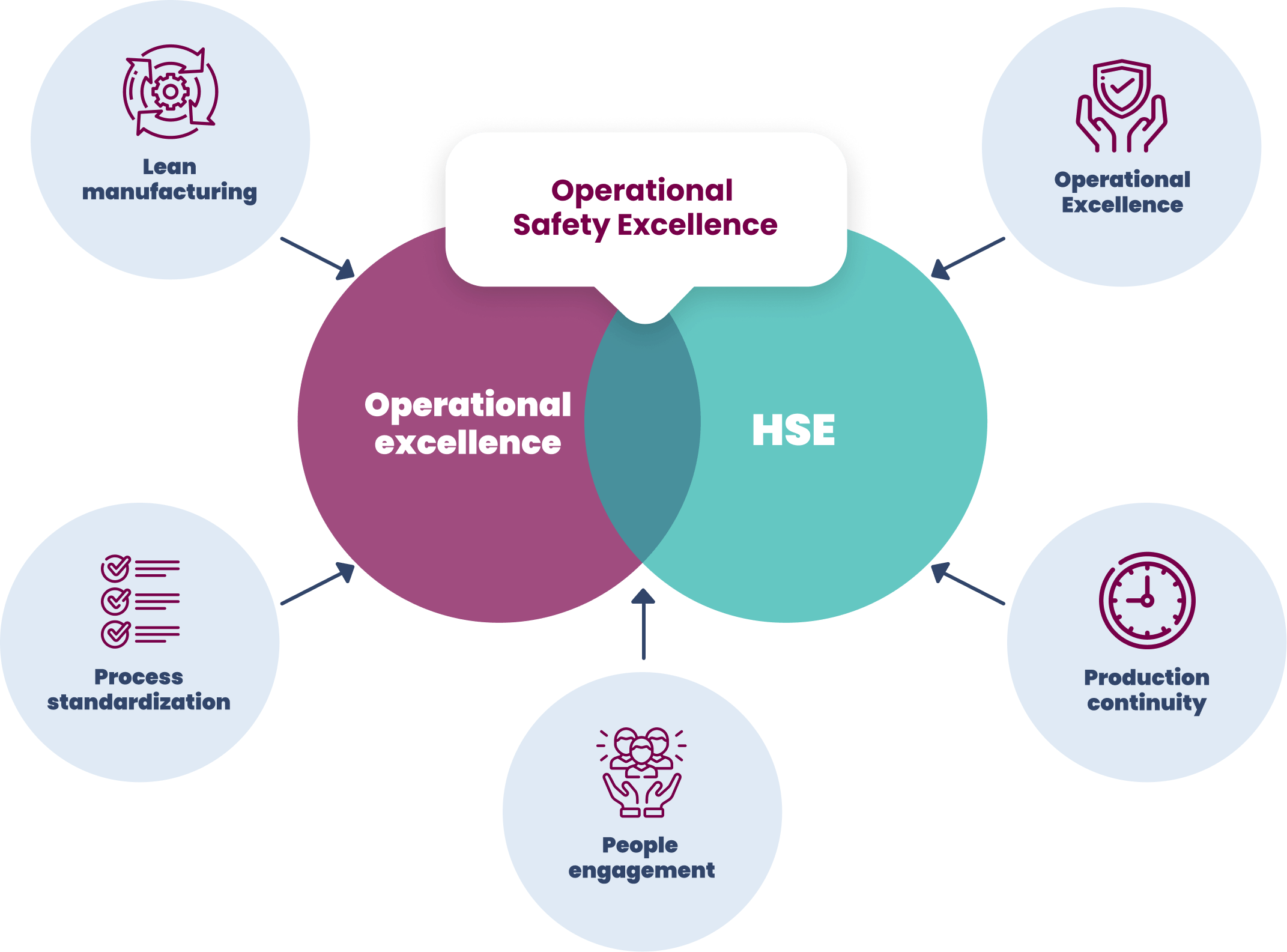

What is the domain of Operational Safety Excellence?

Operational Safety Excellence connects the essential safety carve-out of the Health Safety Environment (HSE) domain with the domain of Operational Excellence.

Operational Safety Excellence focuses on implementing continuous improvement in safety performance by automating safety execution, safety control, and safety assurance in the heart of operations.

This article highlights the main definitions and principles of Operational Safety Excellence.

What is HSE?

HSE (Health (H), Safety (S), and Environment (E)) is the acronym for the methodology that studies and implements the practical aspects of maintaining health and safety at occupation. Furthermore, it concerns the protection of the environment. In other words, it is what organizations should do to make sure that they will not cause any harm to anyone.

- From a safety standpoint, it involves focus, effort, and action to create procedures for identifying workplace hazards and reducing accidents. It also concerns the intended exposure of harmful situations and substances. This requires training of people in incident prevention, incident response, emergency preparedness, and use and instructions of protection (clothing and equipment).

- From a health standpoint, it regards the development of safe, high quality, and environmentally friendly processes, working practices, and systemic activities. These should reduce and/or prevent the chance of risk.

- From an environmental standpoint, it involves creating a continuous approach to comply with environmental regulations. This includes managing waste or air emissions to help sites reduce their carbon footprint.

What is Operational Excellence?

The operational excellence of an organization is the execution of its operations in an excellent way. Given two commercial companies with the same strategy, the operationally more excellent company will in general have better operational results, creating value for customers and shareholders.

Combining Operational Excellence with Safety

The Operational Safety Excellence domain was initially explored by Unite-X (former IB&X) as a safety assurance platform focused on achieving a zero-incident strategy for large industrial industries.

The domain was brought to life to fill the niche between the ever-growing pressure for organizations to comply with Health Safety and Environmental regulations and standards.

While there have been various aspects to creating and maintaining a safe working environment, it is often challenging to implement efficient fail-safe systems and build them in the day-to-day routines. Operational Safety Excellence couples a straightforward zero-incident strategy with process optimization and cost reduction programs.

Five principles of Operational Safety Excellence

- Lean manufacturing

Lean manufacturing, or lean production, is a production method derived from Toyota’s 1930 operating model ‘The Toyota Way”. The term “Lean” was coined by John Krafcik (1988), and defined by James Womack and Daniel Jones (1996) to consist of five key principles: ‘Precisely specify value by specific product, identify the value stream for each product, make value flow without interruptions, let customer pull value from the producer, and pursue perfection.’.

The lean manufacturing methodology focuses on minimizing waste within production processes while simultaneously maximizing productivity. Instead of looking at safety measures as waste or ‘noise’, results have shown how safety aspects and lean processes can reinforce one another.

- Process standardization

Process standardization can be defined as the improvement of operational performance, cost reduction through decreased process errors, facilitation of communication, profiting from expert knowledge, and providing flexibility without sacrificing organizational controls.

The focus of lean manufacturing is standardized work. Within the standardizing principles, this means that every abnormality in the process signals a potential error. When standardizing your processes, working lean means applying principles that can help and be of value for the final quality of your safety processes.

- People engagement

To merge operational excellence with safety execution, people engagement is a key factor. A successful solution is not only supported by the management team, it is especially carried by the people who work with the system.

- Production continuity

Research has shown that downtime is mostly caused by maintenance. When analyzing the duration of maintenance as a whole, you can divide it into preparation/waiting time and actual working and maintenance time. Most of the preparation and waiting times are unnecessarily long and can be lowered by efficient planning and good preparation.

- Operational excellence

To effectively achieve full capacity under the safest circumstances, expertise in the domain of Operational Safety Excellence assures that safety processes are integrated into day-to-day production routines and maintenance environments.

Insights

The true value of managing safety goes beyond the reduction of the direct and indirect costs of serious injuries or the avoidance of catastrophic events.

Firms that manage for safety are more successful and more sustainable because they are focused on operational excellence. Incidents are signs of deviations in the management system and indicate that production is not being managed correctly.

When a business is properly managed for safety, this organization experiences higher production efficiency, higher production quality and provides higher returns for investors.

Unite-X created the domain of Operational Safety Excellence.

To effectively achieve full capacity under the safest circumstances, expertise in the domain of Operational Safety Excellence assures that safety processes are integrated into day-to-day production routines and maintenance environments.